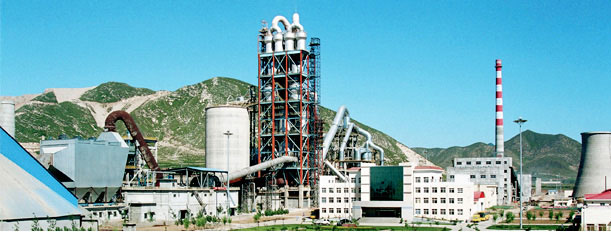

Applications

Waste Heat Recovery Generators

The Kinetic Traction Systems (KTSi) low temperature WHRG can be utilized at multiple locations in the cement production process resulting in continuous power generated from recovered waste heat.

The waste heat recovery systems utilize existing industrial process waste heat energy sources to generate high quality electricity in power ranges from 300 kWe to 500 kWe. The WHRG is designed using Organic Rankine Cycle technology that converts low and medium temperature process heat into electricity via a high speed turbine generator power unit.

Turbo Aerator

The KTSi offers efficient, compact, cost effective aeration solutions for industries that require high quality aeration, such as wastewater treatment, food and beverage, pharmaceutical, and chemical processing. Unlike conventional compressors with lubricated gearboxes, the KTSi uses a single shaft coupling the impeller and direct drive high-speed permanent magnet motor eliminating oil carryover contaminates in the air compression process to comply with ISO 8573 and ISO 12500 quality standards.

Flywheel UPS & Power Quality

Kinetic Traction Systems’ experience in power electronics, power quality, and distributed energy storage allows deployment of GTR Flywheel Energy Storage Systems in a variety of UPS and power quality applications. The flywheels can be configured to provide frequency regulation, voltage stability, demand management (peak shaving), and energy storage in stand-alone or hybrid battery systems. KTSi flywheels are well suited to provide high current output and are able to provide fast response, inrush current for inductive loads, such as motor startup, compressor loads, or medical imaging equipment. The flywheel energy storage can provide fast response backup power ride-through time to start a diesel generator or transfer to another power source. The flywheels can also be configured in series with batteries to significantly increase battery life by absorbing the high frequency, low duration power interruptions, which minimizes battery discharge/charge cycles. KTSi supplies UPS systems with integrated grid inverters or stand-alone flywheel energy storage.

Flywheel Micro-Grid Networks

Using KTSi in-house simulation and analytical tools, cost savings from integrating the flywheel energy storage system in a typical micro-grid application can be estimated. The savings reflect a direct reduction in micro-grid operating costs and CO2 emissions. Flywheel energy storage is ideally suited to renewable micro-grids because of the frequent power fluctuations. A flywheel has high relative power density when compared to batteries, allowing it to rapidly capture energy over a relatively short time without affecting the flywheel performance. The KTSi flywheel system is relatively small and completely silent. In addition, because the system is electro-mechanical, it can be located and packaged remotely from generation sources on the grid. Flywheels can also be operated at a much wider range of operating temperatures compared to other forms of energy storage.

Flywheel Electrified Rail

KTSi GTR flywheels use a fully integrated, permanent magnet, DC motor/generator capturing, storing and regenerating energy. By capturing energy, the GTR flywheel can reduce power consumption and lower costs. Often, the overall capital expense of a GTR flywheel system is significantly less than the installation of a traditional traction power substation. By integrating the GTR flywheel system into a typical metro transit network, the expected energy savings can range rom 15 - 30% (depending on duty cycle, type of train, headway, distance between stations, passenger loading and the size of the GTR flywheel system). The energy savings is directly proportional to the operating electricity cost, CO2 and GHG emission eductions.