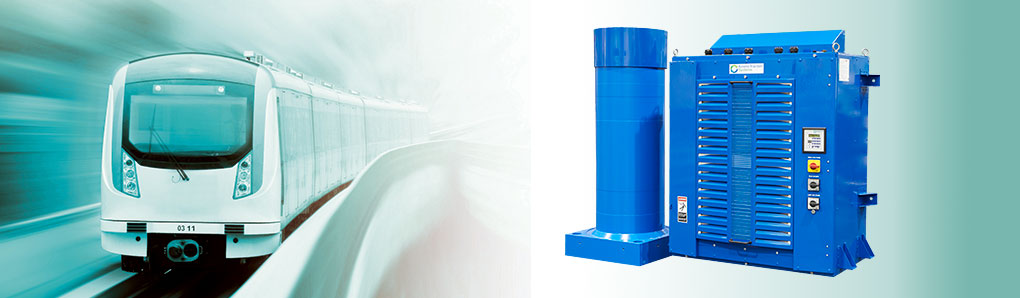

Flywheel Energy Storage Rail

Clean Power Concept: Recovering, Restoring and Recycling Energy

The Challenge

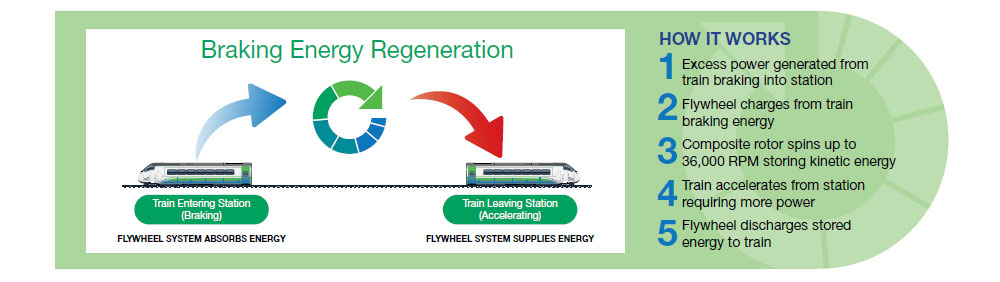

Modern trains brake using traction motors or some combination with friction brakes, creating heat and contributing to equipment operation issues, passenger comfort and heat strain risk. Typically the kinetic energy of the train is dissipated through large electrical resistors or friction brakes thereby wasting the braking energy as heat. Expelling this unwanted heat presents cost, energy and technical challenges. Because trains are heavy and moving at high speed, the amount of energy lost on every braking event is significant. To accelerate the train, the traction motors require “new” power from the electrical supply. This is an expensive use of power that can lead to power demand surges or shortages across the network.

Benefits of Flywheel Energy Storage

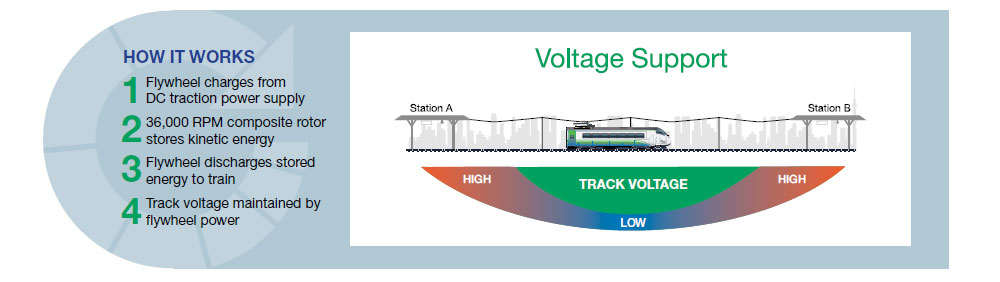

Kinetic Traction Systems (KTSi) GTR flywheels use a fully integrated, permanent magnet, DC motor/generator capturing, storing and regenerating energy. By capturing energy, the GTR flywheel can reduce power consumption and lower costs. Often, the overall capital expense of a GTR flywheel system is significantly less than the installation of a traditional traction power substation.

Saving Energy, Reducing Costs

By integrating the GTR flywheel system into a typical metro transit network, the expected energy savings can range from 15 - 30% (depending on duty cycle, type of train, headway, distance between stations, passenger loading and the size of the GTR flywheel system). The energy savings is directly proportional to the operating electricity cost, CO2 and GHG emission reductions.

Emergency Power

The GTR flywheel system has the ability to provide emergency power in the event of a network power outage. The stored energy in the GTR flywheel can be used to power emergency systems or provide limited “limp-home” capability to the next station or to an area for safe passenger exits.

Long Life

KTSi’s unique high-speed carbon flywheel system features a high cycling, durable, composite rotor running on magnetic and hydrodynamic

bearings up to 36,000 RPM. Each system is capable of delivering 333 kW and more than 1,000 charge-discharge cycles per day for 20 years

with minimal maintenance.